Technical Exploration

- Categories:Technical Exploration

- Time of issue:2021-11-18 14:28:50

- Views:0

1. Application of perlite filter aid in oil industry

Perlite filter aid product introduction

Perlite filter aid is widely used in the filtration process of beer, monosodium glutamate, citric acid, chemical industry, medicine, food, grease and other products as a professional filter medium.

I. How to use:

1. Used alone, perlite filter aid can be used in "5 degreasing" grease filtration, which can achieve degreasing and dewaxing. Such as Samsung grease.

2. Mixed with activated clay, the ratio: 4:1. Due to the loose and porous physical properties of perlite filter aid products, it acts as a support in the filter layer, so it can greatly improve the clarity and filtration speed, and is conducive to the cleaning of filter cloth.

Perlite is an acidic siliceous volcanic glass lava containing crystal water. It is an igneous rock. It was formed by volcanic eruptions hundreds of millions of years ago. Because of the pearl-like cracks in the ore section, it is called perlite in petrography. Like black gangue, turpentine, zeolite, and vermiculite, it is one of the few rocks in the earth's crust that can be processed to expand. Perlite is blasted and excavated in the mine, then crushed by a crusher, sieved into the necessary particle size for expansion, and then preheated at 400-500 degrees Celsius, roasted and expanded at a high temperature of 1180-1350 degrees Celsius, and formed rich in closed and open mouths. The lightweight thermal insulation granular material of pores is called expanded perlite, which is a non-metallic spherical hollow bead that is non-toxic, tasteless, acid and alkali resistant.

II. Introduction of perlite filter aid production process and general use characteristics

Process introduction: ore sand---classification---drying---feeding---calcination/melting--- Cooling---Crushing---Multi-stage selection---Selection---Degranulation---Bagging.

Description: Perlite is puffed and then subjected to grinding and air selection. It is carefully and gently ground in many grades to make the surface of the particles uneven, and the filter cake forming process can only squeeze each other. The final product surface is serrated, and they will bite and connect with each other Forms a rough filtration gap with many inline channels, small enough to block micron-sized particles, but at the same time has a porosity of 80%-90%, which retains a high continuous penetration force.

The special advantage of perlite filter media is that it retains solids while maintaining a high liquid flow rate. It has excellent chemical stability and no potential contaminants. The content of heavy metal ions is generally 0.005%, so it can be used for food-grade filtration.

2. Comparison of manual filling and field expansion, and automatic filling methods

1. Manual filling method

1. It refers to the way that people use cranes or other mechanical lifting equipment to lift the expanded perlite transported to the site after factory production to the top of thermal insulation equipment such as cold boxes, and hire artificially to fill the thermal insulation interlayer. It has the following characteristics: 1. The process is complex and the economy is poor;

2. The number of times of reverse transportation and the serious crushing will reduce the thermal insulation performance of the material itself;

3. There is a lot of dust on the filling site and the pollution is serious;

4. Long time contact with air, the moisture content of the material increases, and the thermal insulation performance decreases;

5. Continuous operation at high altitude has poor safety.

6. It is greatly affected by external factors such as weather, and the construction period guarantee is poor.

Second, on-site expansion, automatic filling method

It refers to the use of movable perlite expansion equipment to expand the perlite ore processed according to a certain particle size grading at the low temperature equipment installation site for on-site expansion production, and use the air transfer method to fill the expanded perlite thermal insulation material into the low temperature. in the thermal insulation layer of the device. It has the following characteristics:

1. Minimize the influence of human factors through automatic control to ensure that the performance requirements of thermal insulation materials are met;

2. The contact between the product and the air is avoided by the airtight conveying method, and the increase of the moisture content of the thermal insulation material is effectively prevented;

3. The use of pulse bag dust removal device for effective dust removal to achieve a dust-free working environment;

4. Pneumatic conveying through pipelines avoids manual high-altitude operations and improves operational safety;

5. By changing the logistics management method, the logistics management cost is minimized and the comprehensive economy is improved;

6. Reduce the impact of environmental factors through closed mechanical operation, and have a reliable construction period guarantee;

7. Through on-site testing equipment, real-time monitoring of the performance indicators of thermal insulation materials can be achieved to improve quality stability.

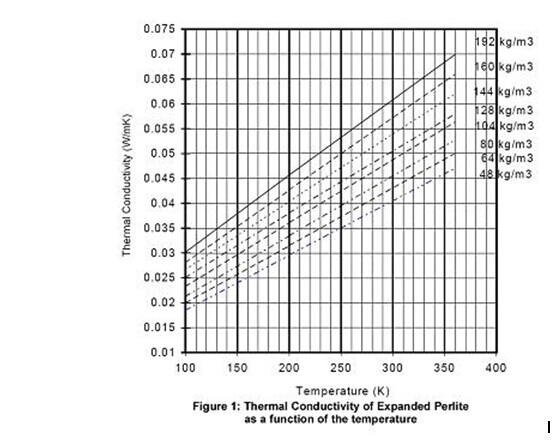

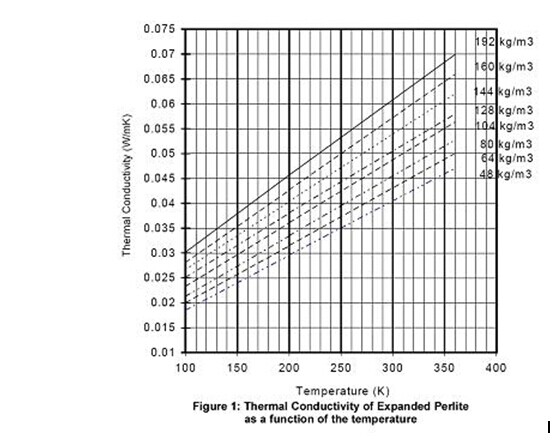

3. How to choose expanded perlite (pearl sand) for cold and heat insulation span>

As we all know, the temperature is transmitted by conduction, convection and radiation. When expanded perlite is filled into the insulation layer of cold boxes and storage tanks, the material between the cryogenic device and the outer protective layer is filled with a microporous structure. Convective heat transfer is negligible due to the viscous effect of air. And because expanded perlite is a dispersion medium, the contribution of radiation to heat transfer is small through scattering and absorption. Therefore, the heat transfer at this time is mainly carried out by heat conduction. At -270K, the heat conduction of perlite is only about 0.022~0.025. Therefore, expanded perlite is widely used as a very excellent cold and thermal insulation material.

The density, particle size distribution, and moisture content of expanded perlite are important factors that directly affect its thermal insulation performance. Inkcom Company, through strict management of raw material origin, physical and chemical indicators, particle size distribution, storage and transportation, etc., utilizes world-class The advanced on-site expansion technology and automatic conveying equipment ensure that the product has the best density and particle size distribution and the lowest moisture content.

· Bulk Density Bulk Density

The loose density of expanded perlite indicates the quality of expanded perlite, that is, porosity. The porosity of unexpanded perlite is too low, and the loose density is large, so the thermal conductivity is large and the thermal insulation effect is poor; while the porosity of expanded perlite is too high, although the loose density is low at first, but the strength of expanded perlite is weakened and it is easy to break. The crushed micropowder enters the micropores, which reduces the porosity, increases the density, and increases the thermal conductivity of perlite. It has been proved by a lot of practice that the loose density of expanded perlite for cold and heat insulation is most suitable to be controlled between 38 and 55kg/m3.

· Compacted Density Compacted Density

In the initial stage after the expanded perlite is filled, the relative position of the perlite particles is not yet in a stable state. After the equipment is running (or vibrating), the particles will gradually move to each other and become stable. This steady state density ultimately determines the cold and thermal insulation properties of expanded perlite. Experiments show that when the tap density of expanded perlite for cold insulation is 48~65kg/m3, its thermal conductivity is the lowest, and the cold insulation effect is the best.

· Moisture Content Moisture Content

Expanded perlite is a very hygroscopic substance. The water absorption rate of dry non-hydrophobic expanded perlite can be 250~750%. Once dry perlite comes into contact with air, it can quickly absorb water molecules in the air. The thermal conductivity of water is 25 times that of air, and water will freeze at low temperatures, while the thermal conductivity of ice is 100 times higher than that of air. In this way, the thermal insulation performance of the expanded perlite after moisture absorption will be greatly damaged. . Therefore, expanded perlite needs to be strictly waterproof and moisture-proof during production, storage, transportation and construction. Under normal circumstances, the moisture content of expanded perlite for cold and heat insulation should be strictly controlled below 0.5% (weight ratio) to prevent moisture damage to the thermal insulation performance of expanded perlite.

· Particle Size Distribution Particle Size Distribution

Reasonable material gradation can occupy the most space through the ideal stacking between particles, form a framework with large particles, smaller particles fill the gaps between large particles, and even smaller particles further fill the spaces between smaller particles. There are gaps to achieve mutual cooperation, so that the free air in the cold insulation area is reduced, and the cold loss due to convection and radiation is minimized. A large number of test data show that when the particles above 1.18mm should be controlled below 10%, the thermal insulation is the best.

· Organic material Content Organic material Content

Organic matter is an unstable component, which will rot and mutate under certain conditions, which will destroy the material structure and affect its thermal insulation effect. Its content should be strictly controlled below 0.1%.

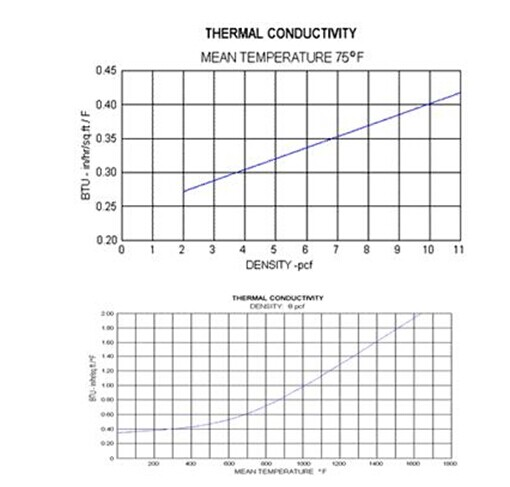

· Thermal Conductivity Thermal Conductivity

The thermal conductivity depends on the comprehensive reflection of the previous items, and it is also the final requirement for cold insulation. Different operating temperature environments have different requirements for thermal conductivity of cold insulation materials. Usually the general requirement of cryogenic industry is 0.022~0.025w/m.k.

5. Detailed explanation of expanded perlite

ExpansionThe resulting perlite becomes a very light internal honeycomb-like white particle. It has the characteristics of non-toxic, odorless, non-combustible and non-rotten. Insoluble in strong acid and alkali, slightly soluble in hydrofluoric acid. The pH value is neutral (6.5-7.5). Due to its special microporous structure, it has a strong adsorption and heat insulation effect, and is often used as a thermal insulation, filtration, and adsorption filter material.

In terms of ultra-low temperature thermal insulation, Inkcom has introduced the most advanced light fuel roasting technology from abroad, selected the perlite resources with the largest reserves and the best quality in Asia, and followed the international ASTM, PI professional quality standards for thermal insulation materials, with ISO9000 The standard of quality control and service is carried out, and the expanded perlite (pearlescent sand) produced for ultra-low temperature insulation meets the special requirements of ultra-low temperature equipment such as air separation plants and cryogenic liquid storage tanks to the greatest extent.

First, the expansion mechanism of expanded perlite

The reason why perlite is different from other rocks and can expand under certain temperature conditions is mainly due to two fundamental reasons. One is that there is a glassy substance with a lower softening point in the main chemical composition of perlite, namely SiO2 , Al2O3, Na2O, etc., the result of this substance is that when perlite is heated to about , its glassiness begins to soften, and the perlite particles gradually transform from solid state to viscous fluid state. The second is that the volatile substances and bound water contained in the perlite are gradually gasified and overflowed after being roasted at high temperature.

Therefore, vitreousness is a prerequisite for the expansion of perlite, and bound water is the internal driving force for the expansion of perlite. The roasting temperature and time are the necessary external conditions for the expansion of perlite.

Second, the main factors affecting the thermal insulation effect of expanded perlite

The bulk density, water content and grain size have the greatest influence on the thermal insulation performance of expanded perlite.

The size of the loose density indicates the quality of the expansion effect of perlite. If the loose density is too large, the expansion is incomplete, the filling density increases, and the thermal conductivity increases; if the loose density is too small, the expansion is excessive, and the material is easily broken during the filling process. As the density increases, the thermal conductivity also increases.

Due to the strong water absorption of expanded perlite, in a water-rich environment, the weight can increase by 4-5 times in a very short period of time, and the thermal conductivity of water is 25 times that of air, so the moisture content of the material increases, It will seriously affect the thermal insulation properties of the material. Usually in large air separation plants, side pipes are designed to introduce nitrogen gas from the side of the heat exchanger into the insulation layer, so as to maintain a positive pressure inside to prevent the moisture in the air from being sucked into the insulation material, resulting in the deterioration of the insulation performance of the material. .

The thermal insulation material should have a reasonable particle size distribution, the purpose is to make the thermal insulation material in the best packing state, if the particle size is too small, the filling density of the material will increase, resulting in an increase in the solid heat conduction of the material; If it is too high, the gas heat conduction between the thermal insulation layers will increase, and the thermal insulation performance will decrease. Therefore, the particle size distribution of the thermal insulation material plays a non-negligible role in achieving the best thermal insulation effect.

Third, the use of expanded perlite

1. Construction field: thermal insulation, fire retardant coatings, sound-absorbing panels, etc.;

2. Industrial field: pipeline insulation, cold and heat insulation, filter material, slag collecting material in steelmaking process, rubber and plastic filling material, etc.;

3. Agricultural and horticultural fields: soilless cultivation, soil improvement, pesticide retarder, etc.

Perlite is a kind of vitreous volcanic rock formed after the acidic lava erupted by volcanoes encounters lakes, oceans, etc. and is rapidly cooled. year. According to the content of internal crystal water, it is divided into obsidian, perlite and turpentine.

I. Mineral Features

1. Main physical properties of perlite

|

Color |

Yellow-white, flesh red, dark green, gray, brown-brown, black-gray and other colors, mainly gray-white-light gray |

|

Appearance |

Fracture jagged, shell-shaped, lobed, white streaks |

|

Mohs hardness |

5.5~7 |

|

Density g/cm3 |

2.2~2.4 |

|

Refractoriness |

1300~1380°C |

|

Refractive index |

1.483~1.506 |

|

Expansion factor |

4~25 |

2. General chemical composition of perlite ore (%)

| Ore type |

SiO2 |

Al2O3 |

Fe2O3 |

CaO |

K2O |

Na2O |

|

Perlite |

70~75 |

12~16 |

0.1~1.5 |

0.1~2.0 |

1~5 |

1~5 |

Second, the main purpose:

Perlite raw sand is finely pulverized and superfinely pulverized, and can be used as filler in rubber and plastic products, pigments, paints, inks, synthetic glass, heat-insulating bakelite and some mechanical components and equipment.

Perlite is expanded to become a lightweight, multi-functional new material. It has the characteristics of light apparent density, low thermal conductivity, good chemical stability, wide operating temperature range, low moisture absorption capacity, non-toxic, odorless, fireproof, sound absorption, etc. It is widely used in various industrial sectors.

III. Development and utilization status and development trend:< br />

1. Development and utilization status, existing problems and solutions

The dominant use of perlite mines at home and abroad is the production of expanded perlite and its products. At present, the annual output of expanded perlite in my country has exceeded 4 million m3, accounting for about 5% of the annual output of thermal insulation materials in my country. It is the most widely used type of lightweight thermal insulation material in China. According to statistics from relevant departments, the current application ratio of expanded perlite in my country is about 60% of construction projects, about 30% of heat pipe insulation, and about 10% of decorative materials, so it is mainly used for building energy conservation and equipment and pipeline insulation.

Although perlite is widely used in various fields and is a dying industry, it has faced severe challenges in some fields, and many materials will replace perlite in the near future. In terms of alternative materials, flaky vermiculite is one of the most competitive materials used as insulation material in the mortar and construction fields. Lightweight aggregates such as pumice, expanded clay, shale and pozzolan, pozzolan, or foamed cement, which

ADD:

Room 710, F South, Haitai Information Plaza, No. 8 Huatian Road, Xiqing District, Tianjin

Copyright ©2022 INCOM 津ICP备**********号-1 Powered by www.300.cn Hotlink:Incom SEO tag

022-28368989

022-28368989

在线留言

在线留言